The Future of CNC Machining: New Trends in Intelligence and Automation

Published on Monday, 17. February 2025

0

With the deepening of Industry 4.0, manufacturing is experiencing an unprecedented technological revolution. As one of the core technologies in modern manufacturing, CNC processing is also continuously advancing towards intelligent and automated development. These new trends not only improve processing efficiency and quality but also open up new possibilities for complex parts to be manufactured. This article will discuss the development trends of CNC processing towards intelligence and automation, and showcase our company's foresight in technology layout, attracting clients who prioritize innovation.

CNC Machining Intelligence: The Crossing from Traditional to Smart

Smart Programming and Adaptive Manufacturing

Traditional CNC programming relies on human experience, while intelligent programming using AI algorithms and machine learning technology automatically optimizes machining paths to reduce idle time, improve processing efficiency. Adaptive machining techniques adjust machining parameters in real-time based on real-time sensor data to ensure the stability and consistency of the machining process.

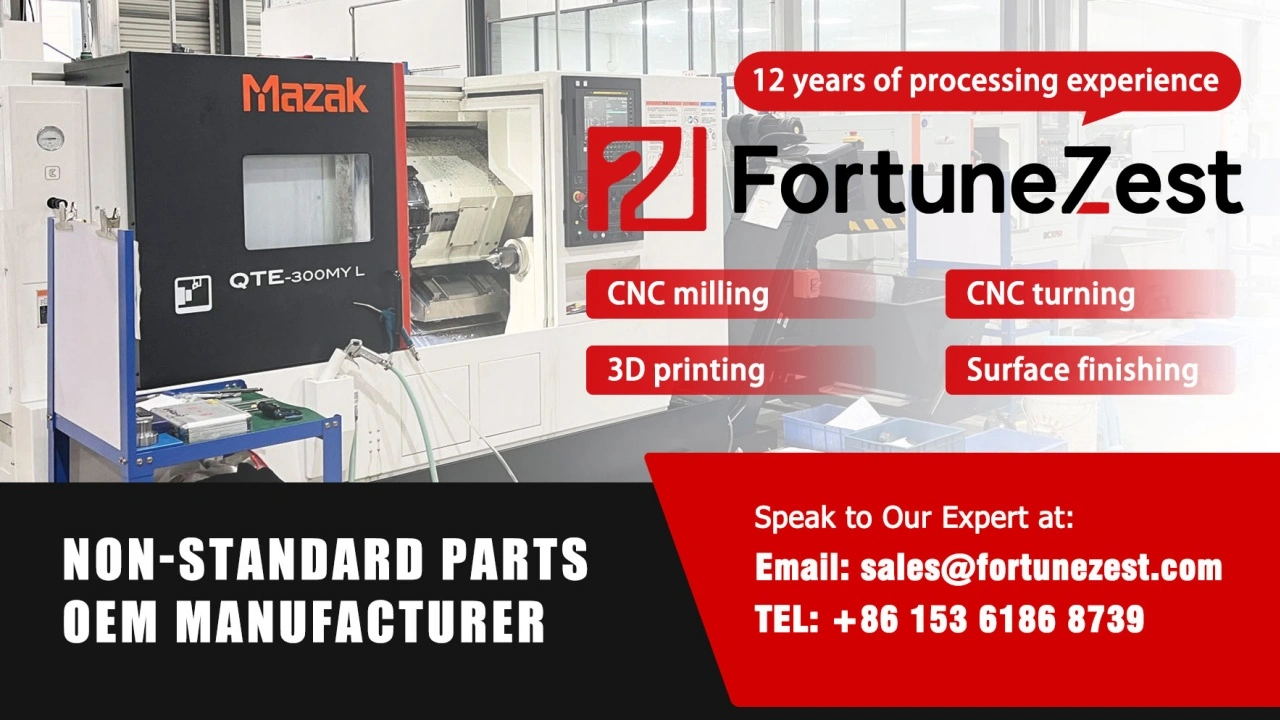

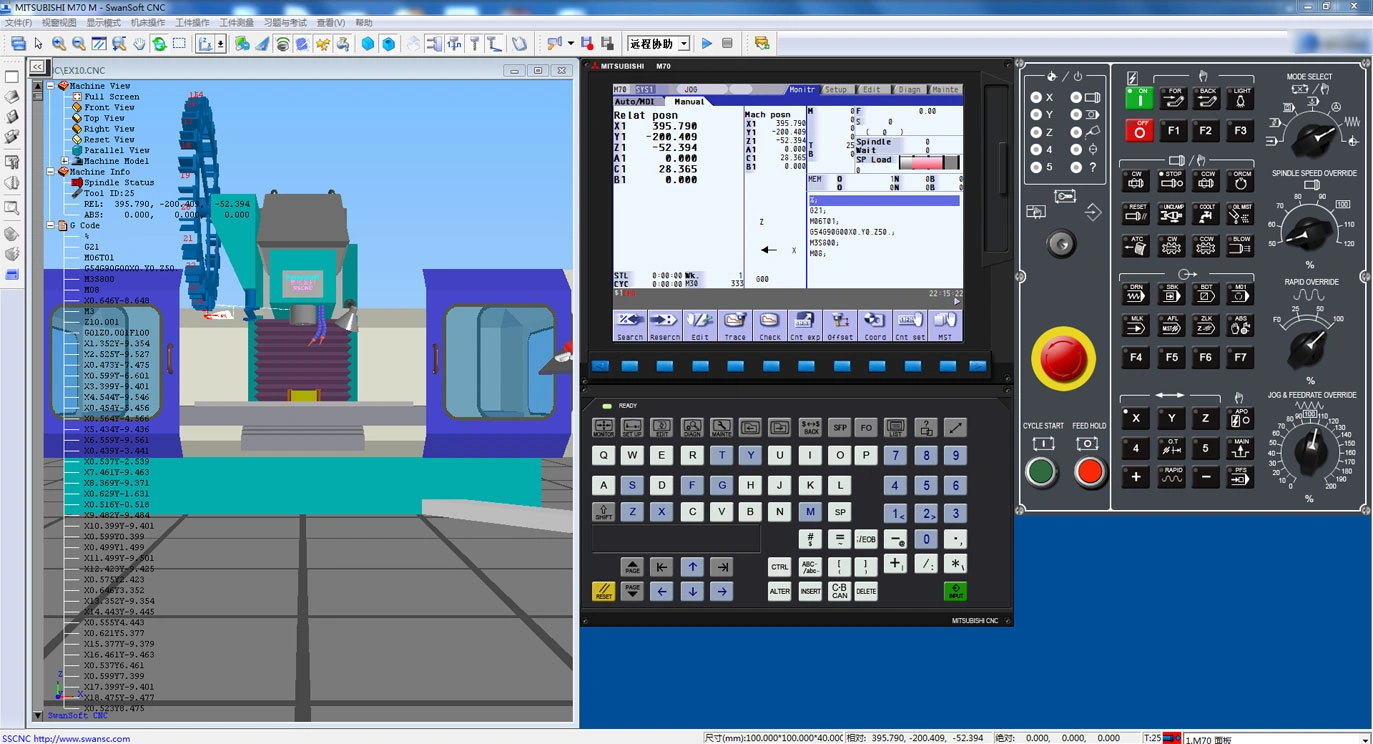

Digital Twin and Virtual Simulation

Digital twins use virtual CNC processing environments to simulate the entire process before actual processing, predict potential problems and optimize processing schemes in advance. This not only reduces the cost of trial runs but also significantly improves the success rate of processing.

CNC Processing Automation: The Foundation of Automated Factories

Automated Loading/Unloading and Robot Integration

The integration of automated loading/unloading systems with industrial robots enables fully unmanned operation of CNC machining processes. Through automatic tool changing, workpiece handling, and inspection, manual intervention is significantly reduced while production efficiency is substantially improved.

Intelligent Warehousing and Logistics Systems

Equipped with RFID technology and automated material handling equipment, the smart warehousing system achieves automatic management of raw materials, semi-finished products, and finished goods. This not only alleviates inventory pressure but also ensures seamless coordination across production workflows.

Company Technology Strategy: Leading Industry Innovation

Our company has always been at the forefront of technological innovation, actively developing intelligent and automated CNC machining solutions. Currently, we are making breakthroughs in the following areas:

Smart Machining Centers: By adopting AI-driven programming software and adaptive machining systems, we have significantly improved the efficiency and quality of complex component processing.

Automated Production Lines:Through the integration of industrial robots and intelligent warehousing systems, we have established highly efficient and flexible unmanned production lines.

Digital Twin Platform: We have developed a CNC machining digital twin system, providing customers with end-to-end virtual simulation services from design to production.

Success Case: Intelligent CNC Machining Empowers High-End Manufacturing

Our company recently completed an intelligent CNC machining project for a medical device enterprise. The project required machining a batch of high-precision titanium alloy parts with complex geometric shapes. Through intelligent programming and adaptive machining technology, we not only reduced processing time by 25% but also increased the product qualification rate to 99.9%. This successful case fully demonstrates the potential of intelligent CNC machining.

Attract innovation-oriented customers

Intelligence and automation represent the future of CNC machining and are pivotal to the transformation and upgrading of the manufacturing industry. With cutting-edge technological capabilities and extensive industry expertise, our company has become the preferred partner for numerous high-end manufacturers.

If you are seeking innovative CNC machining solutions, we invite you to reach out to us. We are committed to providing you with the most advanced technical support to meet your precision manufacturing needs.

Conclusion

The future of CNC processing belongs to automation and intelligence. Our company will continue to focus on technological innovation, providing more efficient and precise machining solutions for our customers. Let's work together to usher in the intelligent future of manufacturing!

Previous:No More/End

Next:No More/End